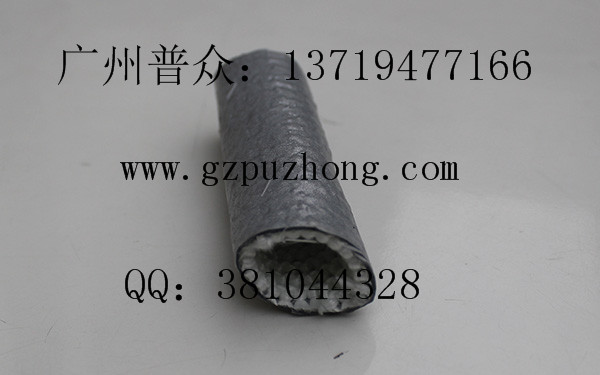

耐 热 套 管

Withstands continuous exposure to 260℃ (500℉)

Up to 1090℃ (2000℉) for 15~20 minutes

Up to 1650℃ (3000℉) for 15~30 seconds

Size:1/4”(6mm) ~ 5”(127mm)

Thermal conductivity (K-Factor):

Industrial grade K=0.541 BTU-in./hr-ft2-℉

Aerostyle grade K=0.610 BTU-in./hr-ft2-℉

Electrical insulation capacity (Dielectric breakdown voltage):

Average Dielectric Breakdown Voltage 7.3kV

Min. Dielectric Breakdown Voltage 5.0kV

Max. Dielectric Breakdown Voltage 10.0kV

Chracteristic: greaseproof, waterproof, excellent modulus of elasticity

resists molten metal splash

承受持续温度:260℃ (500℉)

承受 1090℃ (2000℉) 约 15~20分钟

承受瞬间 1650℃ (3000℉) 约 15~30秒

尺寸:1/4英吋 (6公厘) ~ 5英吋 (127公厘)

导热系数(K-Factor):

一般工业品级 K=0.541 BTU-in./hr-ft2-℉

航天工业品级 K=0.610 BTU-in./hr-ft2-℉

绝缘性能 (电介质破坏电压数):

平均值:7.3kV;最小值 5.0kV;最大值 10.0kV

特点:防油、防水、阻挡熔铁喷溅

耐 热 套 管

Constructed from a high bulk fiberglass sleeve heavily coated with iron oxide red

silicone rubber, Pyrojacket sheds molten metal splash and withstands intense heat

and flame, making it ideal for protecting hoses, cable and tubing in a variety of

hostile environments. Withstands continuous exposure to 500℉ (260℃), up to 2000

℉ (1090℃) for 15-20 minutes, and up to 3000℉ (1650℃) for 15-30 seconds.

以高膨松性玻璃纤维之套管所制成,并覆以厚实的氧化铁红硅胶,耐热套管能阻挡熔铁喷溅,

且不受高温和火焰所损坏,这些性质使其适用于保护恶劣环境下的软管、缆线和管路。耐热

套管可连续暴露于 500°F (260°C)的高温中而不受损坏,高达 2000°F (1090°C)的温度下可承

受 15-20分钟,3000°F (1650°C)的温度下则可承受 15-30秒。

Available in size up to 5” (127mm) diameter, Pyrojacket has an excellent modulus

of elasticity and can be used to bundle hoses and cables.

耐热套管尺寸齐全,最大直径达 5英吋 (127公厘),且拥有绝佳的延展系数,极适合用于包

覆软管和缆线。

Pyrojacket’s insulation properties allow it to provide effective burn protection for

personnel from hot hoses and piping, while reducing costly heat energy losses.

Available in both Industrial and Aerostyle grades.

耐热套管的阻绝特性除了能够有效避免人员遭受高热管线的烧烫伤害,更能大幅节约热能源

流失的成本。耐热套管备有一般工业品级和航天工业品级可供选择。

Also available in other colours by special order.

可依需求提供多种颜色选择。

PJ-04 PJ-05 PJ-06 PJ-07 PJ-08 PJ-10 PJ-12 PJ-14 PJ-16 PJ-18 PJ-20 PJ-22 PJ-24 PJ-26

PJ-28 PJ-32 PJ-36 PJ-40 PJ-44 PJ-48 PJ-52 PJ-56 PJ-60 PJ-64 PJ-72 PJ-80

PJA-05 PJA-06 PJA-07 PJA-08 PJA-10 PJA-12 PJA-14 PJA-16 PJA-18 PJA-20 PJA-22

PJA-24 PJA-26 PJA-28 PJA-32 PJA-36 PJA-40 PJA-44 PJA-48 PJA-52 PJA-56 PJA-60 PJA-64